Initiatives for Reducing the Environmental Burden

Disclosure of Environmental Information

While striving to comply with various environmental laws, regulations, and ordinances, we are actively disclosing environmental information related to the synthetic rubber and elastomer manufacturing and sales business in ENEOS Holdings' ESG Data Book.

Improvement of Local Environments

In addition to installing combustion treatment equipment for synthetic rubber drying exhausts at the Yokkaichi, Kashima, and Chiba Plants in FY2006 and FY2007 as a countermeasure for odors, we also installed a ground flare at the Yokkaichi Plant in FY2008 as a countermeasure for noise and light pollution. We are working on continuous improvements to further reduce odors by sealing odor sources and spraying a special deodorizer developed jointly with a deodorizer manufacturer.

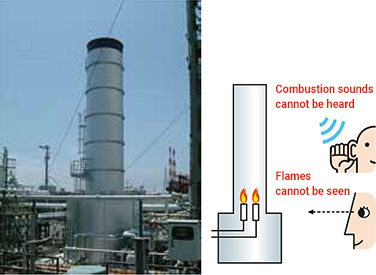

Ground Flare (Yokkaichi Plant)

The combustion takes place in a ground-mounted cylindrical furnace, which minimizes the impact on the surrounding environment.

Regenerative Thermal Oxidizer (Chiba Plant)

We have introduced a regenerative thermal oxidizer into the synthetic rubber finishing process for the highly efficient treatment of volatile organic compounds (VOC).

Wastewater Treatment Facility (Chiba Plant)

We treat factory wastewater using oil-water separation, pressure flotation, activated sludge, and biological treatment equipment, and strive to maintain and manage emissions below the standards set by the Water Pollution Control Law and Environmental Conservation Agreement.

Reduction of our greenhouse gas emissions

To achieve the ENEOS Group's targets (46% reduction of GHG emissions* by 2030; net-zero GHG emissions by 2050), we are promoting energy-saving activities at each plant and the conversion to fuels with lower CO2 emissions (natural gas, biomass, etc.)

- Scope 1 and 2, compared to FY2013