High Performance Polymers

High Heat-Resistant Thermosetting Resins

Characteristics

- High heat resistance due to original epoxide

- When the temperature is raised, it becomes liquid and has low viscosity

- High filling of filler due to low viscosity

- Low coefficient of thermal expansion and high thermal conductivity due to high filling of filler

Physical property comparison with traditional epoxy resin

| Traditional resin | XR0004 | XR0016 | XR0014 | XR0020 | |

|---|---|---|---|---|---|

| Main resin (Epoxide) | Biphenyl etc. | ENEOS resin [Low viscosity] |

ENEOS resin [High Tough] |

ENEOS resin [Low Temp. cure] |

ENEOS resin [Low Temp. cure2] |

| Hardner | Phenol | ||||

| Property | |||||

| Viscosity@100degC [Pa・sec] |

>5 | 0.3 | 0.8 | 0.8 | 0.9 |

| F. Strength*[MPa] | 150 | 124 | 155 | 140 | 138 |

| F. Modulus*[MPa] | 3000 | 4820 | 3800 | 4400 | 4060 |

| Tg(175℃5h)[℃] | <200 | - | - | 190 | 210 |

| Tg(220℃5h)[℃] | <220 | 240 | 220 | 240 | 250 |

- Post cure condition:100℃2min → 180℃1h → 220℃5h

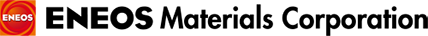

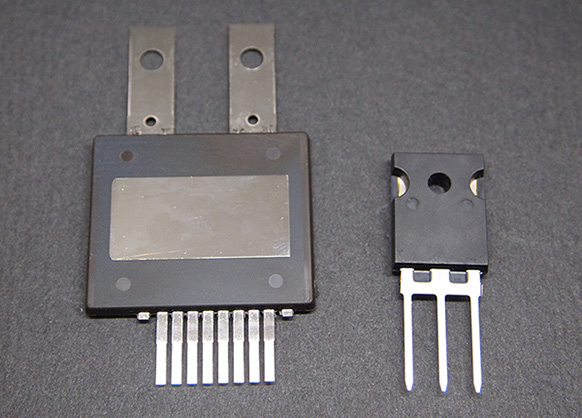

Application:Thermosetting compound

Low CTE & High heat resistant compound

| Traditional compound | Prototype#1 | Prototype#2 | |

|---|---|---|---|

| Main resin (Epoxide) | Traditional resins | XR0014 | XR0020 |

| Hardener | |||

| Filler type | Spherical silica | Spherical silica | Spherical silica |

| Filler content[wt%] | 85 | 85 | 85 |

| Property | |||

| Spiral flow[cm] | 135 | 150 | 140 |

| Gelation time[sec] | 40 | 45 | 40 |

| Tg[℃] | 133 | 190 | 210 |

- Post cure condition:175℃3min → 175℃5h

The low CTE compound has higher Tg while having the same spiral flow and gel time as traditional compound.

The low CTE compound is used as an encapsulant that has both high heat resistance and low CTE.

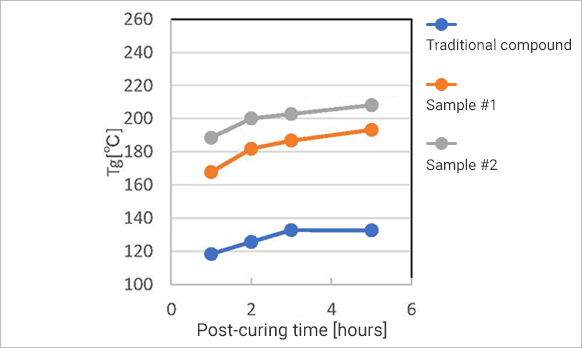

High thermal conductivity compound

| Traditional compound | Prototype#3 | |

|---|---|---|

| Filler content[%] | Alumina etc:85 | Alumina etc:≦90 |

| Binder | Traditional resin | XR0014 |

| Tg[℃] | <200 | 240 |

| F.strength[MPa] | 120 | 100 |

| F.modulus[MPa] | 30000 | 45000 |

| Thermal conductivity[W/m・K] | 4.5 | 9.0 |

- Post cure condition: Traditional compound: 175℃3min → 175℃5h, Prototype#3: 175℃3min → 220℃5h

Low viscosity allows high filling of heat conductive fillers.

High thermal conductivity compound achieves 9W/ mk when it is highly filled with alumina etc.

Contact Us